1 Million Gallon Potable : AquaVers® 405

MARKET: Potable Water : Drinking Water Reservoir

SYSTEM: AquaVers® 405 Potable Water Approved Polyurea

PROJECT: 1 Million Gallon Drinking Water Reservoir : Protective Coating

OWNER: City of Blaine, Washington

CONTRACTOR: Vector Construction with Tiger Construction

Together with Tiger Construction LTD, Vector Construction recently conducted a job to remove an old tar tank liner in a one million gallon water tank for the city of Blaine, Washington. The specification called for the installation of a new polyurea lining system that meets the requirements of NSF/ANSI 61-5 potable water standards that was eventually applied by Vector Construction Inc., out of Port Townsend, Washington.

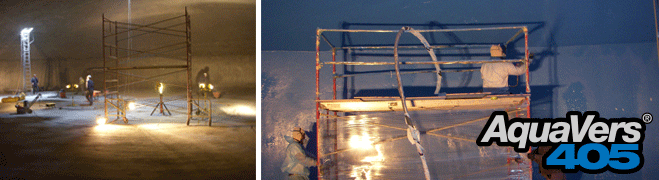

The existing 22,000 square foot tank had old and deteriorated concrete. The jobsite was riddled with unusual factors that made the job more difficult and challenging for the contractor. The jobsite had no power utilities or water on site. Standing sound waves made ear protection a must at all times. The old tar liner made adequate lighting a challenge. All the equipment and supplies had to be lowered through a 30”x30” access hole or a 36” round vent at the top of the dome.

In addition to the challenges listed above, the tank’s concrete roof leaked every time it rained and ground water was leaking in at the cold joints.

In order to accomplish the job, the crews had to remove 20 cubic yards of an old tar liner, old caulkíng, and creosote soaked oakum from large cracks in the floor. The tank was then blasted to the appropriate surface profile, pressure washed and vacuum cleaned.

Propane heaters, large fans and dehumidifiers were used to dry out the tank and regulate the temperature and humidity. A large tarp was laid over the tank top to control rainwater intrusion during the application.

Zypex was used for leaks and a latex fortified patching compound was utilized on the larger spalls. The fìoor cracks were prepped, primed with Quick Mender and filled with a joint filler to complete the repair.

The surfaces to be coated were sprayed and backrolled with AquaVers 20 Primer. The portion of the dome above the water line that was not scheduled for polyurea, was also sprayed with a rust preventive primer.

When the time came for the polyurea lining, three Gusmer/Graco H-20/35’s were used to apply AquaVers 405 to a final dry film thickness (DFT) of 90 mils. The spray applicatìon was continuous to insure a seamless liner.

When the weather allowed, the tarp was removed and two coats of a solvent free silicone coating was applied to the dome.