Fort Nelson: VF 380 Pre-Manufactured Geotextile Panels

MARKET: Containment : Pre-Sprayed Geotextile Panel

SYSTEM: VF 380 Elastomeric Spray Polyurea

PROJECT: Earthen Process Pond over Geotextile approx. 70,000 ft² (21,300 m²)

OWNER: EOG Resources, BC Canada

CONTRACTOR: Hyperion Technologies Inc., Calgary, Alberta, Canada

EOG Resources has various drilling and processing sites throughout Canada. Along with this, containment ponds are required for the process water containing various chemicals. Being aware of environmental issues related to leaks and spills of chemicals, a seamless, flexible system was required. Hyperion Technologies proposed a synthetic geo-membrane / polyurea based on the VersaFlex VF380 polyurea spray elastomer system, as opposed to a sheet-good liner system based upon a thermoplastic material.

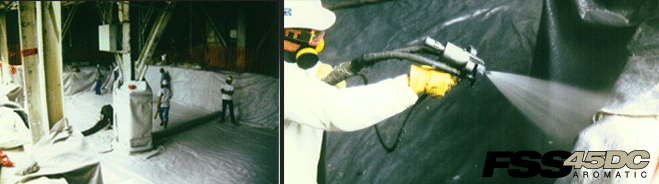

This work could only be accomplished during the winter when the ground area is frozen for excavation. VF380 / Geotextile was chosen as the liner system for this application due to elastomer performance, flexibility and installation ability in extremely cold weather. A nominal 60 mils (1.5 mm) composite VF380 / Geotextile system was installed.

The VF 380 / Geotextile polyurea spray elastomer panel system (patent pending work) was prepared in a controlled shop environment by Total Containment Solution in Florida. The prepared panels (15’ by 40’, 4.6m by 12.2m) were manufactured such that approximately 6” to 8” (15.2 cm to 20.3 cm) perimeter of geotextile was left uncoated for the complete installation processing in Canada. A minimum average 60 mil (1.5 mm) composite panel was prepared using the VF 380 PUA over the 4-oz spun bonded geotextile fabric. A stipple texture was applied to each panel, which were then rolled and shipped to the project site.

At the project site (-20°C ambient temperature), the panels were then unrolled and VF 380 was applied at the overlap areas of the panels to form a uniform liner system.

VersaFlex’s VF 380 is specially formulated for geotextile application and possesses excellent bonding capability to previously applied VF 380 material. Material storage was minimal as only the overlap areas were being coated with the VF 380 system. A heated trailer and tent area was used to keep material warm for processing / application.