Backyard Deck and Bar : WB 250 Waterborne

MARKET: Protective Coatings : Wooden Deck and Bar

SYSTEM: WB 250 Waterborne Urethane, Aliphatic ClearCoat, 45DC, 50DM

PROJECT: Restoration Backyard Patio / Deck / Bar

OWNER: Rob Crawford, MCC Equipment, Indiana

CONTRACTOR: MCC Equipment, Indianapolis, Indiana

Rob Crawford is no stranger to commercial coatings. Rob is the founder and owner of MCC Equipment in Indianapolis, IN. MCC is a highly recognized supplier of plural component coatings equipment. Everyday Rob and his team are in the field servicing the technical equipment needs of protective coatings applicators around the world.

Last Spring, Rob was faced with refurbishing his household residential deck. This deck was the site of many family parties and the center of entertainment for his beautiful Indianapolis home. Like most homes in Indiana, the weather plays a major role on the life cycle of outdoor structures such as wooden decks, concrete driveways and more.

For years Rob had serviced his deck at least once per year with the old standby, go to product we all know too well, Thompson’s Water Seal. Maybe its all the marketing hype or the years of advertisements, but this is pretty much the wood deck sealer of choice for DIY (do-it-yourself) weekend warriors. The only problem is that it didn’t really work all that well, and had to be re applied year after year to have any life at all.

Since Rob was familiar with pretty much all of the commercial coatings used by industry to protect steel and concrete in high end industrial applications where performance is an absolute must, he figured he would try something different. Rob also had all of the technical expertise and even the state of the art equipment used to apply these commercial protective coatings. So after years of following the DIY route with hardware and paint store consumer products, Rob decided to notch it up a level when it came time to repeat the process again last year.

Rob was going to go “industrial” on his residential wooden deck. And industrial he went. So one day last spring, Rob began the final rehab to his household outdoor entertainment deck.

The first step was to get it ready for the makeover. They utilized a 3-stage process of bleach and water deck wash, power wash and sanding in the major areas. Upon completion of the cleaning and preparation stage, the areas to be re-sealed were taped off, and the application process commenced.

With all of Rob’s expertise in the commercial protective coatings arena, he knew there was only one supplier’s materials to use for the project, VersaFlex® Incorporated, a leading supplier of Polyurea protective coatings, joint sealants, and industrial concrete repair products. Rob selected VersaFlex WB250 Waterborne Urethane Coating for the project. WB 250 is color stable and applied in thin mil coats. They applied two very light coats for the initial base coat and then applied WB 250 clear with 50% water in two more heavier mil coats to give the deck an excellent wear surface, UV color stable protective and decorative finish.

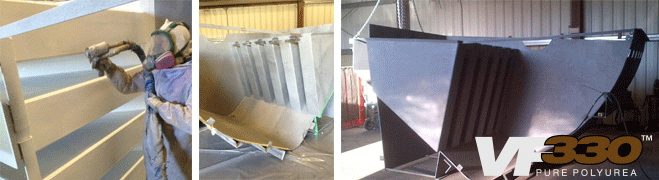

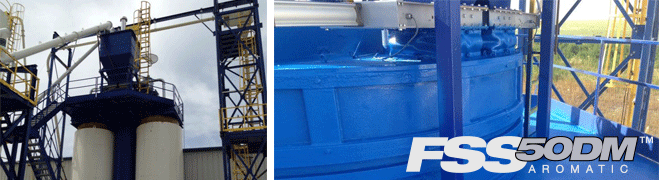

Now for the rest of the deck, or more specifically the bar, he ratcheted it up and went even more industrial with a pure polyurea from VersaFlex® called FSS 50DM. All the black out panels were constructed of ½ inch blue board sprayed with the polyurea. The bar top itself was built with ¾ inch plywood sprayed with VersaFlex FSS 45DC, another pure polyurea product in the color grey. The bar top was then top coated using VersaFlex Aliphatic Clear Coat (ACC) mixed with fine grain black onyx, white calcium, gold spec and brown spec sprayed through an air operated gelcoat cup gun. Four coats were applied with a wet sand process in between. The bar was finished with two more coats of ACC in clear finish for the final coat.

The bar and deck are now now four years old and it appears they will be lasting quite bit longer with little to no maintenance after this industrial strength coatings makeover. It stands as beautiful now as the day he finished it and it has seen more than its fair share of snow storms, rain, shoveling, leaves and yard service. According to Rob “with a commercial/industrial polyurea product from VersaFlex, ingenuity, and some cold beer, there is nothing that can’t be accomplished around the house.”