GPP-glas, Vienna Public School: SL/75 Joint Filler

MARKET: Joint Systems : Window Glass Application

SYSTEM: SL/75 Joint Filler

PROJECT: Glass Plate / Metal Construction, School Building, Vienna

OWNER: Public School, Vienna, Austria

CONTRACTOR: GPP Glas GmbH / Schoerkhuber-Huemer OEG

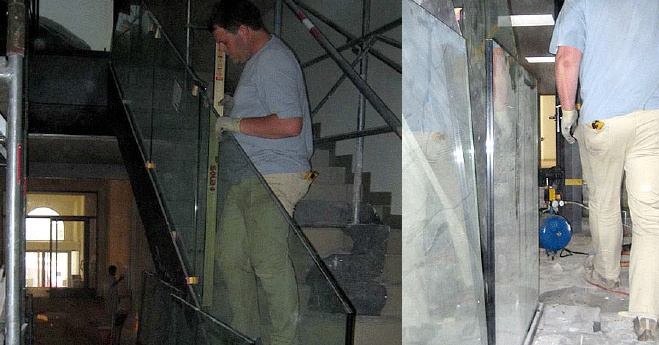

GPP Glas specialized in doing glass work in a very special field, starting from the design of glass-based LED lightning combinations through to protective solutions for glass in staircases. In a project for a public school in Vienna, Austria, they began working to find a new solution to a glass plate style construction.

To secure the heavy glass plates, each element weighing about 220 lbs, being composed of double security glass, the company had previously used a water-based joint-filling system, which had to be worked out in a ratio of 1:3.

Past problems included a wide range of quality issues, from overly reactive material or batches which mixed poorly. In addition, the system itself was very tricky to handle (tack-free time of about 10 minutes, reactions with water resulted in foaming).

There are intricate logistics needed to secure the glass plate elements – first at the edges to fix them exactly in balance, then filling the tubes completely. This results in a construction method which requires many waiting periods, while the system in the tube set up inside, closing the pipe. This workflow had been typical for any staircase in public school buildings and government buildings.

The first test with VersaFlex’s SL/75* was done on the 7th of May, 2008.

“At this test we used a Gama G-250H (in the absence of any other appropriate unit) in combination with a “no-name“ low-pressure gun with static mixer. After a practical application at which the client got all the information regarding how it would work with their system, including a way to work out the system more efficiently with moveable units, and a double cartridge system with pneumatic gun.”

“At the end of this testing day the client made some tests, to check the system itself, the retention forces and re-calculated the application time and the progress of the day. The conclusion of the client’s tests showed that the new system was superior, and the client immediately ordered 120 lbs of VersaFlex SL/75 in a double-cartridge system including the pneumatic gun and the “Easy Spray” unit from Gama.”

The double-cardridge system arrived only 4 days after ordering on place in Vienna via air-freight, mastering all the ordering administration and customs procedures, so the client was able to work out this public school building project in record time, without any problems.

Finishing works were done on the 13th of may, 2008.