Burlington WWTP: VF-380™ Over Spray Foam

MARKET: Water & Wastewater: Anaerobic Digester Tanks

SYSTEM: VF-380™ Elastomeric Polyurea over Medium Density Spray Foam

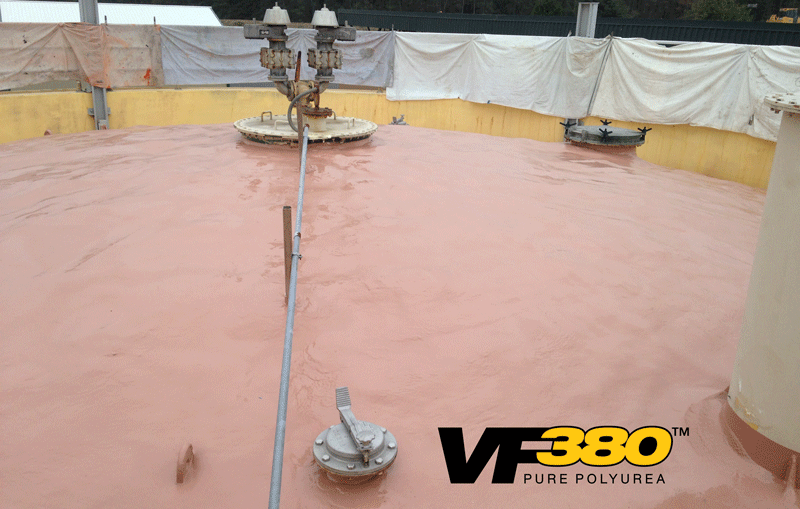

PROJECT: Anaerobic Digester Tank Lid Protection – 3,200 sq ft

OWNER: Burlington Wastewater Treatment Plant, Burlington, WA

CONTRACTOR: Cascade Indstustries N.W., Bothell, Washington, USA

A wastewater treatment plant in Burlington, WA. needed to repair and restore two 45’ Diameter Anaerobic Digester tank lids and selected VersaFlex pure polyurea as the solution.

The project was roughly 3200 sq ft in size and consisted of a one (1) inch thick base of spray polyurethane foam insulation topcoated with pure polyurea (VF-380™), one whose physical characteristics are a perfect for spray foam. The polyurea topcoat was applied at an average thickness of 80-90 mils.

The wastewater treatment facility’s digester lid project took only two (2) days to complete in full. A five (5) man crew from Cascade Industries N.W., a leading polyurea applicator in the region used a Graco 20-35 Pro with a P2 gun set-up to prep, spray the foam, and apply the VersaFlex VF-380™ pure polyurea.

Interestingly enough, while on the job the team discovered that that digester tank walls were also sprayed with polyurea almost 18 years prior. The polyurea was also from VersaFlex — FSS 45DC™, their flagship protective coating for concrete. The polyurea was noted to be performing extremely well after 18 years in service.

The VF-380™ system used as the topcoat on this project is especially well-suited for use in tandem with spray foam. The VF-380™ is a very low-shrinkage polyurea and therefore has no adverse effects over the spray foam when applied properly.