Wastewater Clarifier Rehabilitation : FSS 50DM Polyurea

MARKET: Water & Wastewater : Clarifiers

SYSTEM: FSS 50DM Elastomeric Polyurea

PROJECT: Wastewater Clarifier Tank Rehabilitation

OWNER: Petrochemical Plant, Rayong, Thailand

CONTRACTOR: International

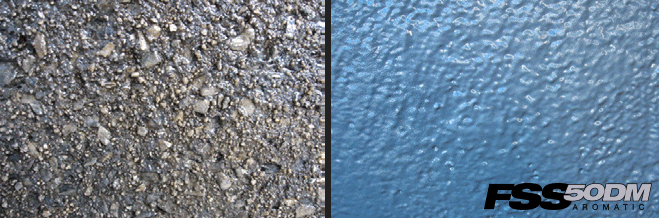

After years of neglect, one of the wastewater clarifier tanks at a petrochemical plant in Rayong, Thailand needed serious attention. The concrete substrate and existing liner had been damaged over the years, and at the start of the project had been leaking wastewater for months.

Conventional repair procedure would require cement mortar to be applied, leveling the surface, prviding strength and smoothness before applying a protective coating. Cement mortar repair plus the required protective coating with FRP or Epoxy can take up to 3 weeks [20+ days] to complete.

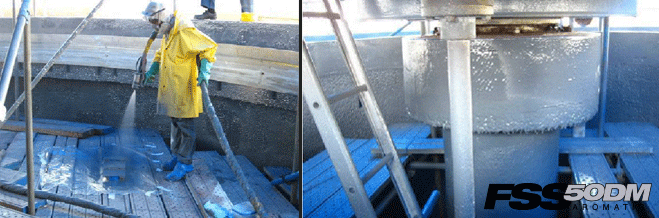

However, with VersaFlex’s FSS 50DM pure polyurea protective coating system, there is no need for a cementitious mortar application prior to installing the seamless elastomeric liner. FSS 50DM bonds well with rough surface profiles such as this, after a high-pressure wash to remove any loose contaminants / debris.

After the initial preparations were complete, FSS 50DM was applied at a thickness of between 60 and 80 mils. Because the system is monolithic, seamless, and extremely easy to apply, total rehabilitation time of the clarifier tank was only 3 days.