Magnesium Corporation: FSS 50DM

MARKET: Waterproofing : Pipeline Rehabilitation

SYSTEM: FSS50DM Aromatic Elastomeric Spray Polyurea

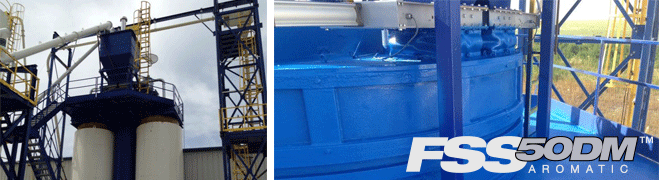

PROJECT: Sealing Corrosion holes in Header Pipe (while in service)

OWNER: Magnesium Corporation of America

CONTRACTOR: Systems Development Services Inc.

Internal corrosion of this 220’ section of header pipe at Mag Corp was causing a serious problem. Due to budget constraints, the company’s primary objective was to extend the life of the pipe by as much as 2 years. The problem was to find a way to encapsulate a large section of pipe that had a negative operational pressure of 4 to 8 lbs. The pipes content of chlorine gas, along with a surface temperature of 200 degrees F, created a series of problems in the repair procedures.

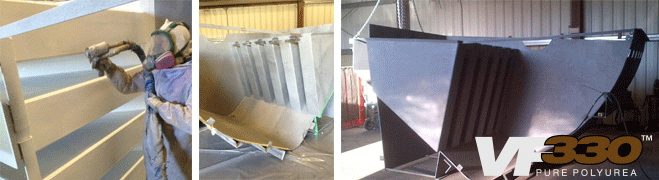

Once the pipe was sand blasted, it was determined that neoprene patches and VersaFlex FSS-50DM could be used to seal all of the holes. The pipe would then be recoated with 85-100 mils of FSS-50DM Polyurea coating. By sealing off all of the holes, the pipe would no longer pull in moisture, which when combined with chlorine gas created HCL. Solving this dilemma eliminated further interim pipe corrosion and achived Magnesium Corporations primary objective.