Timber Ridge Potable Water Tank: AquaVers™ 405 & FSS 45DC™

MARKET: Potable Water Delivery

SYSTEM: AquaVers™ 405, FSS 45DC™ Pure Polyurea

PROJECT: Timber Ridge Tank Rehabilitation (500,000 gallons)

OWNER: Mammoth Community Water District, Mammoth Lakes, California

CONTRACTOR: TopLine Engineers, Hayward, California

Potable water is a precious commodity, and in many cases the infrastructure used for storage doesn’t get much attention until a problem is identified. However, once a problem becomes evident, the rehabilitation of these massive storage tanks can be a major concern, both financially and environmentally for the counties and municipalities who count on them for fresh water. Often the aging infrastructure and supporting technologies (coatings, linings, piping, etc.) is deteriorated beyond the point of a simple rehabilitation patch job, at which point it’s time to look for a system that is extremely durable, environmentally safe, and long-lasting.

The Mammoth Lakes Community Water District found themselves in exactly this position with one of their 500,000 gallon potable water tanks, and needed to find a solution quickly. After submitting a bid for the job, TopLine Engineers was selected to handle the complex project using VersaFlex AquaVers™ 405 Potable Water Polyurea coated fabric for the interior of the tank, and VersaFlex FSS 45DC™ Pure Polyurea coated fabric for the exterior of the tank. TopLine recommended VersaFlex products to ensure reduced downtime, reduced need for extensive concrete rehab and preparation, and because they are a superior material selection for extended service.

- Before the coatings could be applied, many preparations needed to be made:

Dewatering and disposal of approximately 55,000 gallons of chlorinated potable water, which was remaining in tank after initial draining of tank by OWNER. - Installation of temporary storage tanks, piping, valves and conduit for temporary relocation of existing level transducer for existing pump control.

- Demolition of existing piping and filling existing pipe penetrations for tank fill, tank outlets, and tank overflow piping.

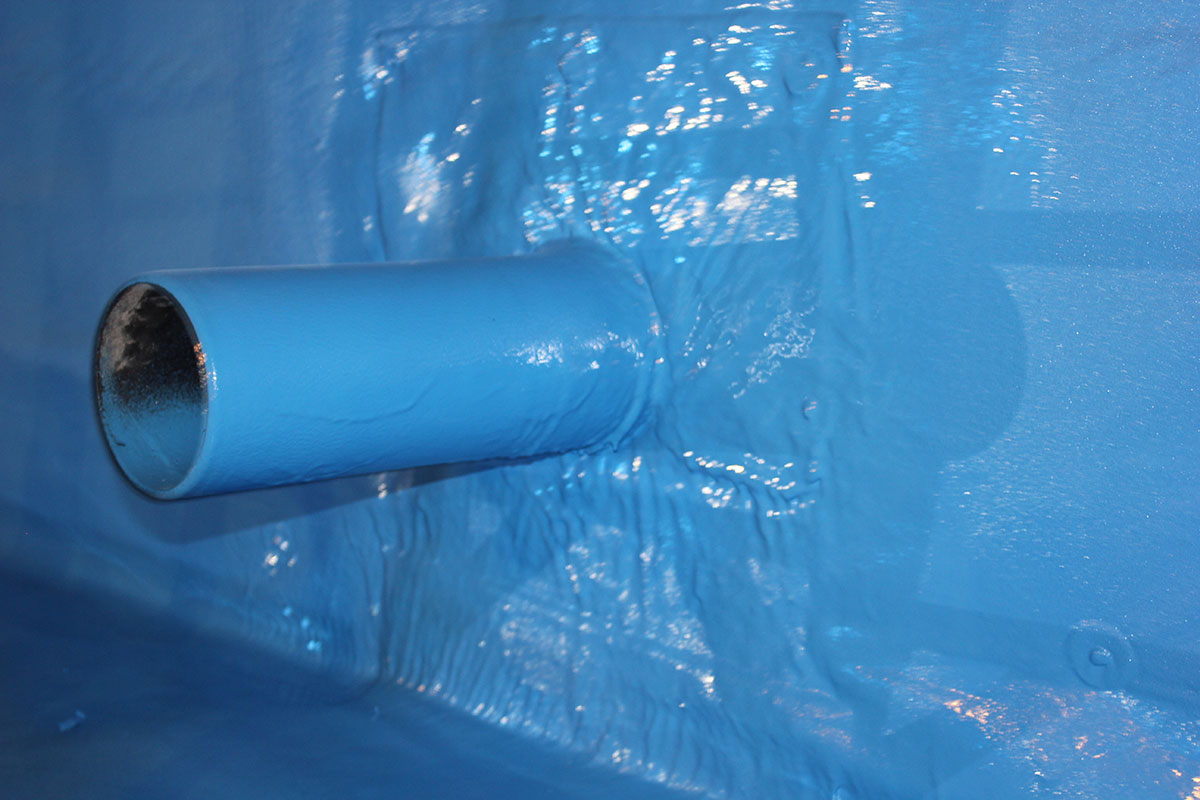

- Core drilling existing tank wall for new fill, outlet and overflow pipe penetrations and installing new piping with modular mechanical seals to accommodate new liner / coating.

- Abandoning existing 6” steel outlet piping and relocating existing 6” ductile iron fill piping to near-floor level.

- Installing new 12” diameter ductile iron pipe for roof vent.

- Repairing portions of deteriorated concrete.

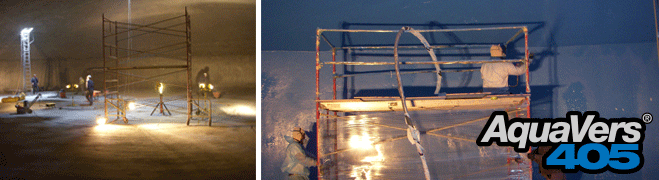

Once these steps were completed, application of VersaFlex materials could proceed. For the top of the tank, it was necessary to remove the existing coating and repair the degraded areas using a polymer modified cement. Subsequently, fabric was laid out with 6 inch overlaps at all seams. Care was taken to ensure that the geotextile was positioned to conform to the surface irregularities as much as possible. Excessive wrinkles were avoided.

Fabric was fastened to the concrete substrate using Hilti stainless steel powder-actuated fasteners with 2” Stainless Steel washers to fasten horizontal surfaces at all seams at approximately 4-feet on center and a maximum of 5-feet on center in each direction between seams. On vertical surfaces the same power-actuated fasteners with washers were used to fasten all seams at approximately 2-feet on center and a maximum of 3-feet on center in each direction between seams. Terminations were fastened using either powder-actuated fasteners with washers. Each fastener was spot sprayed before and after install to insure adequate seal. An initial tacking coat of FSS 45DC™ polyurea (in Ryno Gray) at 10-15 mils was used as an adhesive to hold the fabric during placement and fastening, and then was spray coated to a minimum thickness of 80 Mils. High winds during spray application of the lid slowed down the process, and a few extra days were expended waiting for more favorable spray conditions.

After draining the tank, it was evident that the existing coal tar epoxy was riddled with water-filled blisters. Removing the failing coating added a delay before installing the fabric PUA system. Dehumidification was not necessary because of the dry climate. The same fabric application and spray procedures were adhered to as above. Liner termination was above the water line and direct to the prepared concrete substrate. AquaVers™ 405 polyurea was sprayed to a minimum of 80 mils on the interior, over the applied fabric.

Both interior and exterior portions were completed using Graco EXP-2, 150ft of hose, Fusion AP using 4242, 2222 tips. These were housed in a mobile box truck with a tow behind generator for power.

While this project can be simplified to highlight the use of VersaFlex materials, there were many factors that complicated the job:

- Weather delays – High winds (15 mph + were common) high altitude (~8500 ft ASL)

- Accessibility – Steep slope project location with unimproved dirt road access

- Vandalism – Dehumidifier/genset vandalized during first week.

- Unspecified piping found during excavation / rework. Change orders for additional work.

- Condition of tank lid concrete was worse than bid estimates. Concrete repair scope was expanded to include rehabilitation of damaged areas.

- Interior coal tar epoxy was in worse shape than expected when the tank was emptied. This required additional work to remove the failing coating.

- During interior spray inspections pieces of concrete were found wedged behind the liner in some vertical spots. These chunks were removed by cutting the liner and then seamlessly patching the penetrated area. The spalled concrete pieces were identified as popouts from the powder-actuated fasteners.

During design VersaFlex was chosen by engineers (Water Works Engineers) for our knowledge and experience with Polyurea and proper specification. VersaFlex continued to support the specification efforts with Mammoth Water District to rehab the concrete using PUA instead of Hypalon or other sheet good membranes. Multiple applicators bid the job, but only Topline possessed the general contractor licensing required to bid / complete the entire project. With continued support from VersaFlex, Mammoth Water District felt comfortable moving forward with Topline Engineers as the contractor. At the completion of the job, VersaFlex / TopLine were immediately referred to a 27,500 sq. ft. reclaimed water pond as well as an additional water tank slated for spring 2017.

About TopLine Engineers:

Headquartered in Hayward, California, Top Line Engineers are a licensed, bonded and insured General Contractor business serving the Bay area and beyond. Top Line Engineers provide a wide range of services, including specialty walls and ceilings, insulation services, demolition, abatement services, solar energy, and much more. Identifying the huge potential for polyurea applications, Top Line has recently focused their efforts to target the the water and wastewater markets.