Redstone Arsenal Water Reservoir: AquaVers® 405

MARKET: Potable Water Systems / Water & Wastewater

SYSTEM: AquaVers 405 : NSF/ANSI 61.5 Barrier Material

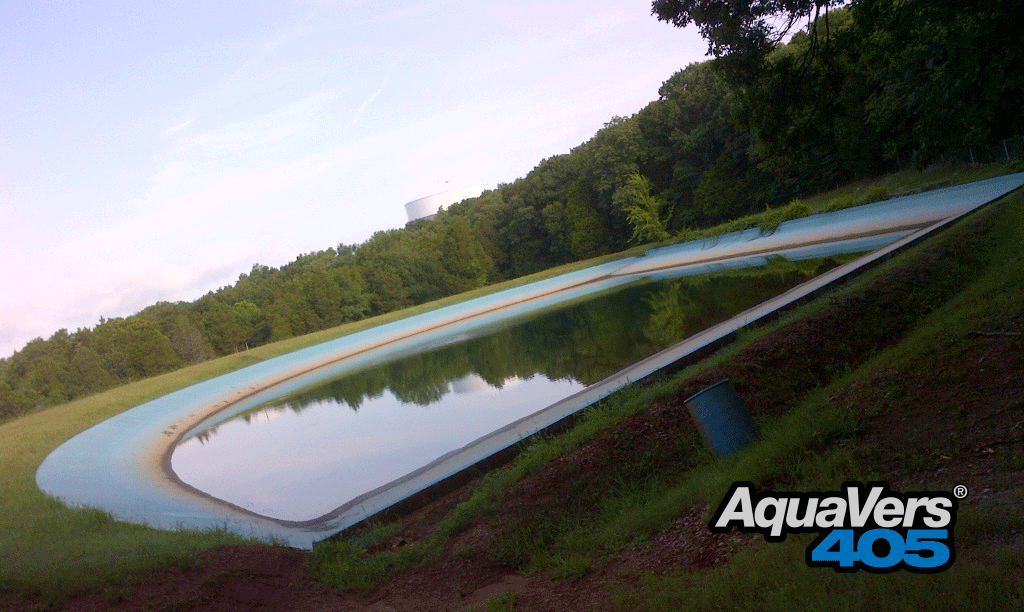

PROJECT: 54,000 gallon Water Reservoir rehabilitation

OWNER: Redstone Arsenal Base, Huntsville, Alabama

CONTRACTOR: Contracting and Materials, Decatur, Alabama

Redstone Arsenal presented a 54,000 sq ft concrete water reservoir, built in the early 1960’s. It functions as a water supply for the base’s fire suppression system, but may at times be used in their potable water supply. The concrete structure has seen several hand-applied coatings, geotextile membranes, and finally an HDPE membrane.

Unfortunately, water had worked its way under the membrane(s) causing them to float, thereby reducing the retained water volume as well as loss of water due to leaks in the concrete. The water engineers at the Department of Public Works at Redstone speci?cally requested a direct to concrete flexible coating be applied which would last in outdoor conditions. In addition, the potable water requirement dictated that the coating have NSF/ANSI 61-5 approval.

Contracting and Materials proposed removing all the sheet good membranes and as much of the underlying old coating as possible, and then applying VersaFlex AquaVers 405 with VF 20 Primer as a base.

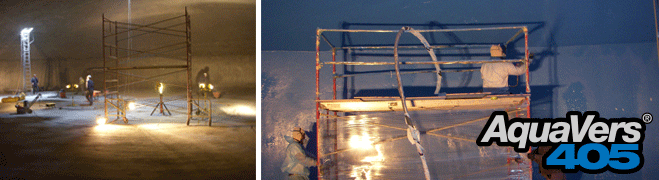

It required a full week for C&M to remove the old liner material, and 2 layers of old geotextile. Another month was allocated to remove the old coatings and prep the concrete surface. Another 2 weeks to repair damaged concrete and expansion joints.

Finally they were able to apply the VF 20 primer by spray and then backrolling to approximately 20 mils over the surface. C&M staged the primer application to stay just ahead of applying the AquaVers 405 to stay within the window of application. AquaVers 405 was applied at an average of 80 mils.

The tank was refilled with water immediately after completion of the coating and is currently in use with complete success.

Contracting and Materials is a specialty coating applicator with over 13 years of experience. They have 6 employees who have completed the Polyurea University Level 1, 2, and 3 courses. In addition to applying VersaFlex polyurea they also provide epoxy and ceramic coatings.