FMD Vaccine Plant: VF 350™ & Aliphatic Clearcoat™

MARKET: Protective Coatings : Virus Protection at Vaccine Manufacturer

SYSTEM: VF 350™ Polyurea & Aliphatic Clearcoat™

PROJECT: Virus Barrier in new FMD Vaccine Plant

OWNER: Multinational Animal Drug and Vaccine company

CONTRACTOR: Thermolex, LTDA – Sao Paolo, Brazil

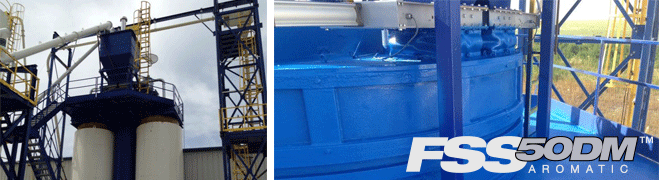

The world’s largest FMD (Foot and Mouth Disease) vaccine plant was recently completed in Brazil, a facility that is owned by a large multinational animal drug and vaccine company. The floor, walls and ceiling required a coating system that would provide a high level of bacteria protection, water resistance, chemical resistance, and which would also be easy to clean.

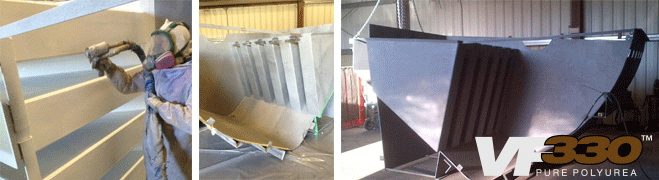

With almost 68,000 square feet of area to coat, the job was awarded to Thermolex, LTDA of Brazil due to its highly qualified and Polyurea University certified team of professionals.

Originally, it was decided that a two-part system polyurea system provided by VersaFlex® be applied to the floor, wall, and ceiling consisting of VersaFlex’s VF 20™ primer followed by 2.5 – 3mm of aromatic VF 350™ pure polyurea.

However, due to a late design change replacing the original lighting with LED lighting, it was determined that a top coat be applied on the walls and ceiling. VersaFlex’s Aliphatic Clear Coat system was selected for a greater level of safety and aesthetic appeal. The polyaspartic system was applied to a thickness of 2.5mm.

From start to finish, the project took 4 months to complete. Preparation of the wall and ceiling surfaces consisted of pressure washing using a standard 4,000 psi pressure washer, followed by sanding using hand tools. The floor received pressure washing and light scarifying to create a profile on the concrete. The polyurea system was applied using a Gusmer H-20/35 plural component proportioning pump.