MidAmerica Coatings: VF 380 + Geotextile

MARKET: Secondary Containment : Geotextile

SYSTEM: VF 380 Elastomeric Polyurea, VF 20 Modified Epoxy Primer

PROJECT: Oil Containment Liner

OWNER: Gas & Oil Transfer Facility

CONTRACTOR: Mid-America Coating Systems

When the Regional Manager for a gas and oil transfer facility needed to upgrade their containment dikes he knew he wanted to use a polyurea liner. He had just recently heard about polyurea at a meeting he attended but had no idea who to contact. After an extensive search, he determined that Mid-America Coating Systems was the right choice. Not only did they have the ability to install the liners but also had a vast amount of experience with all types of industrial and commercial coating applications.

Mid-America Coating Systems has been installing coatings, including polyurea and spray foam all over the U.S. for the past 12 years. Dennis Davidson, President of Mid-America Coating Systems is a second generation foam and coatings contractor having 32 years of application experience installing these products on industrial and commercial projects.

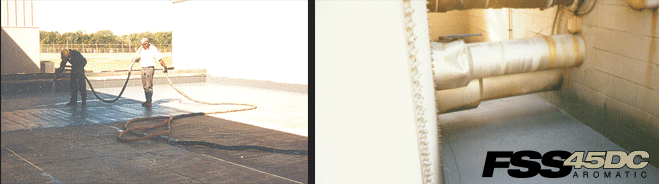

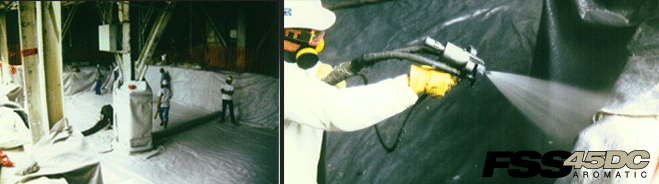

The geotextile was then covered by a minimum of 80 mils of VersaFlex VF380. VF380 was the material of choice because of its toughness, flexibility and its slower reacting time which enables the polyurea to penetrate the surface of the concrete and into the fabric before setting creating a complete bond between all surfaces. To complete the project, a series of slip-resistant walkways were installed using the VF380 and embedding ceramic granules into the wet coating.

At completion, a water test was done to make sure the liner was performing to specifications and did not leak. As expected, the liner passed with flying colors.