Kitchen Floor: SL/75 & Quick Mender®

MARKET: Floor Coatings : Refurbishing / Sealing

SYSTEM: SL/75 Joint Filler, Quick Mender® Concrete Repair System

PROJECT: Kitchen Floor Rehabilitation

OWNER: Private : Atria Management

CONTRACTOR: B & H Coatings, Hebron, MD

After several years using an epoxy coated floor in the commercial kitchen area, Atria Salisbury management decided that the floor had been used past its service life. The replacement of the floor using epoxy would require a kitchen shutdown of several days, which was not satisfactory to the Owner.

B & H Coatings was consulted about alternative solutions for floor coating replacement. The requirements were discussed and a need for speed of installation and return to service as well as the installation of an easily cleanable surface was determined to be paramount. B & H recommended using VersaFlex pure polyurea as the proposed floor coating product.

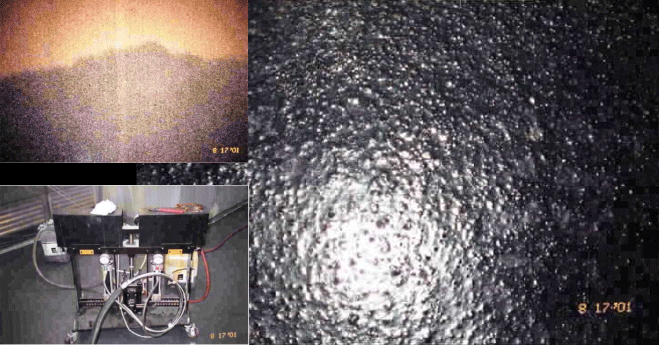

B & H cleaned grease and dirt from the deteriorated epoxy system and then sanded the existing floor surfaces to provide a profile for system adhesion.

After cleaning and profiling the floor, PW-1 primer was installed. SL/75 pump grade polyurea, normally used as a joint filler material, was spray applied to the primed floor using special low-pressure variable ratio equipment supplied by GlasCraft. The SL/75 was standard dark gray aromatic polyurea.

After 30 minutes, 10 mils of Quick Mender® was applied to the polyurea as a seed coat binder. Silica sand was broadcast into the Quick Mender® to refusal. After 30 minutes excess, unbonded sand was removed from the floor system and Quick Mender® was applied at 15 to 20 mils as a locking coat.